How an Optical Fibre Diameter Analyser Enhances Top Quality Control in Fibre Production

The combination of an Optical Fibre Diameter Analyser right into Fibre production procedures stands for a significant improvement in top quality control approaches. By using real-time, specific dimensions of Fibre diameters, this innovation attends to the critical requirement for uniformity in production criteria.

Significance of Fibre Diameter Measurement

Accurate measurement of Fibre Diameter is critical in the area of optical Fibre modern technology, as it straight affects the efficiency and dependability of Fibre optic systems. The Diameter of an optical Fibre influences its light-carrying ability, depletion, and general transmission efficiency. Precision in measuring Fibre Diameter makes sure that the optical residential properties are preserved within specified tolerances, which is vital for optimum signal stability.

Variations in Fibre Diameter can cause boosted losses because of scattering and modal diffusion, influencing the high quality of data transmission. In high-speed communication systems, such discrepancies can result in substantial deterioration of signal quality, leading to information errors and reduced efficiency. Constant Fibre Diameter is important for compatibility with ports and splicing technologies, which are indispensable parts of Fibre optic networks.

Quality control procedures in Fibre production heavily depend on exact Diameter dimensions to make sure compliance with market standards. By carrying out robust dimension strategies, producers can improve item dependability, decrease waste, and enhance total system performance. Therefore, the importance of Fibre Diameter dimension can not be overstated, as it works as a foundation in the innovation of optical Fibre innovation and its applications in modern-day communication networks.

Exactly How the Analyser Functions

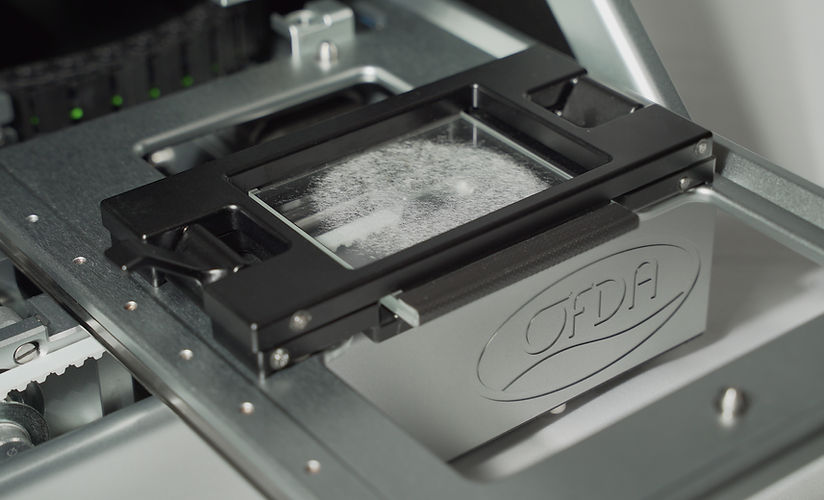

The effective dimension of Fibre Diameter relies on sophisticated logical techniques that make sure accuracy and reliability in optical Fibre manufacturing (optical fibre diameter analyser). The Optical Fibre Diameter Analyser employs a mix of laser modern technology and advanced image handling algorithms to precisely analyze the Diameter of fibres as they are created

Originally, a laser beam is directed at the moving Fibre, producing a cross-sectional darkness. The analyser captures this shadow utilizing high-resolution electronic cameras placed purposefully along the production line. The captured pictures are then refined in real-time to determine the Fibre's Diameter with outstanding precision.

The system makes use of sophisticated algorithms that account for various elements, including variations in light strength and ecological problems, to boost dimension integrity. It can detect minute changes in Diameter, such as fluctuations that might occur throughout the production process.

Additionally, the analyser can dealing with multiple fibres simultaneously, raising throughput without endangering precision. By providing instant feedback on the Diameter, the Optical Fibre Diameter Analyser plays a crucial duty in preserving strict quality assurance criteria, making certain that the end product meets sector specs and customer needs.

Advantages of Real-Time Monitoring

While typical techniques of keeping track of Fibre Diameter frequently entail lengthy post-production checks, real-time monitoring significantly improves the efficiency and top quality of optical Fibre production. optical fibre diameter analyser. This proactive strategy enables producers to identify variances in Fibre Diameter web as they occur, rather than waiting till production is complete to analyze quality

By continuously gauging the Diameter throughout production, makers can ensure that the fibers fulfill strict requirements, resulting in lowered variability and enhanced uniformity. Real-time tracking additionally allows immediate rehabilitative actions to be taken, reducing waste and protecting against faulty fibres from going into the supply chain.

Moreover, this innovation assists in boosted data collection and evaluation, giving insights into production patterns and possible locations for renovation. Such data-driven decision-making encourages makers to optimize procedures and preserve high criteria of quality control.

Additionally, real-time monitoring promotes a society of continuous renovation within the production environment. Employees are much more involved when they can see the effect of their work in real-time, bring about heightened accountability and a commitment to excellence. In general, the application of real-time tracking systems in optical Fibre manufacturing equates to exceptional product high quality and enhanced consumer fulfillment.

Influence on Production Efficiency

Executing optical Fibre Diameter analysers significantly enhances manufacturing performance by simplifying the production process. These gadgets assist in constant tracking of Fibre Diameter, permitting makers to find variances in real-time. By determining disparities quickly, manufacturing lines can be changed rapidly, minimizing downtime and lowering the probability of creating defective items.

Moreover, the integration of these analysers right into the manufacturing workflow makes it possible for much better resource appropriation. With precise Diameter dimensions, operators can maximize material use, making certain that resources are not wasted on problematic fibres. This accuracy likewise adds to less rework and ditch, ultimately decreasing production prices.

The automation supplied by optical Fibre Diameter analysers decreases dependence on manual examinations, which are commonly time-consuming and susceptible to human mistake. Consequently, workers can concentrate on more critical tasks, improving total efficiency.

In addition, the data produced from these analysers can educate process renovations and help with far better decision-making. By analyzing patterns in Fibre Diameter variations, producers can apply proactive measures to improve manufacturing techniques and keep constant top quality. In recap, optical Fibre Diameter analysers play an important duty in increasing production performance, resulting in greater top quality result and increased success.

Situation Researches and Success Stories

Throughout numerous sectors, study highlight the transformative effect of optical Fibre Diameter analysers on manufacturing procedures. One noticeable instance is a leading telecoms firm that encountered challenges with irregular Fibre sizes, bring about increased rejection rates. By integrating an optical Fibre Diameter analyser, the firm attained real-time surveillance of Fibre measurements, leading to a 30% decrease in defects and significant cost savings.

Furthermore, a research establishment focusing on advanced products utilized optical Fibre Diameter analysers to fine-tune their speculative processes. The analyser's capacity to supply detailed understandings into Fibre uniformity enabled the growth of innovative products with improved performance features.

These success tales emphasize the vital duty of optical Fibre Diameter analysers in boosting quality look at these guys control, enhancing manufacturing efficiency, and driving advancement throughout diverse markets.

Verdict

In final thought, the Optical Fibre Diameter Analyser plays a pivotal role in enhancing quality control within Fibre manufacturing. As shown via numerous situation research studies, the analyser verifies essential for achieving superior item top quality in Fibre manufacturing.

The application of optical Fibre Diameter analysers permitted for strict top quality control, making certain that the generated fibres satisfied exacting industry requirements.In conclusion, the Optical Fibre Diameter Analyser plays a critical duty in enhancing high quality control within Fibre production.